Tips for purchasing an excavator track

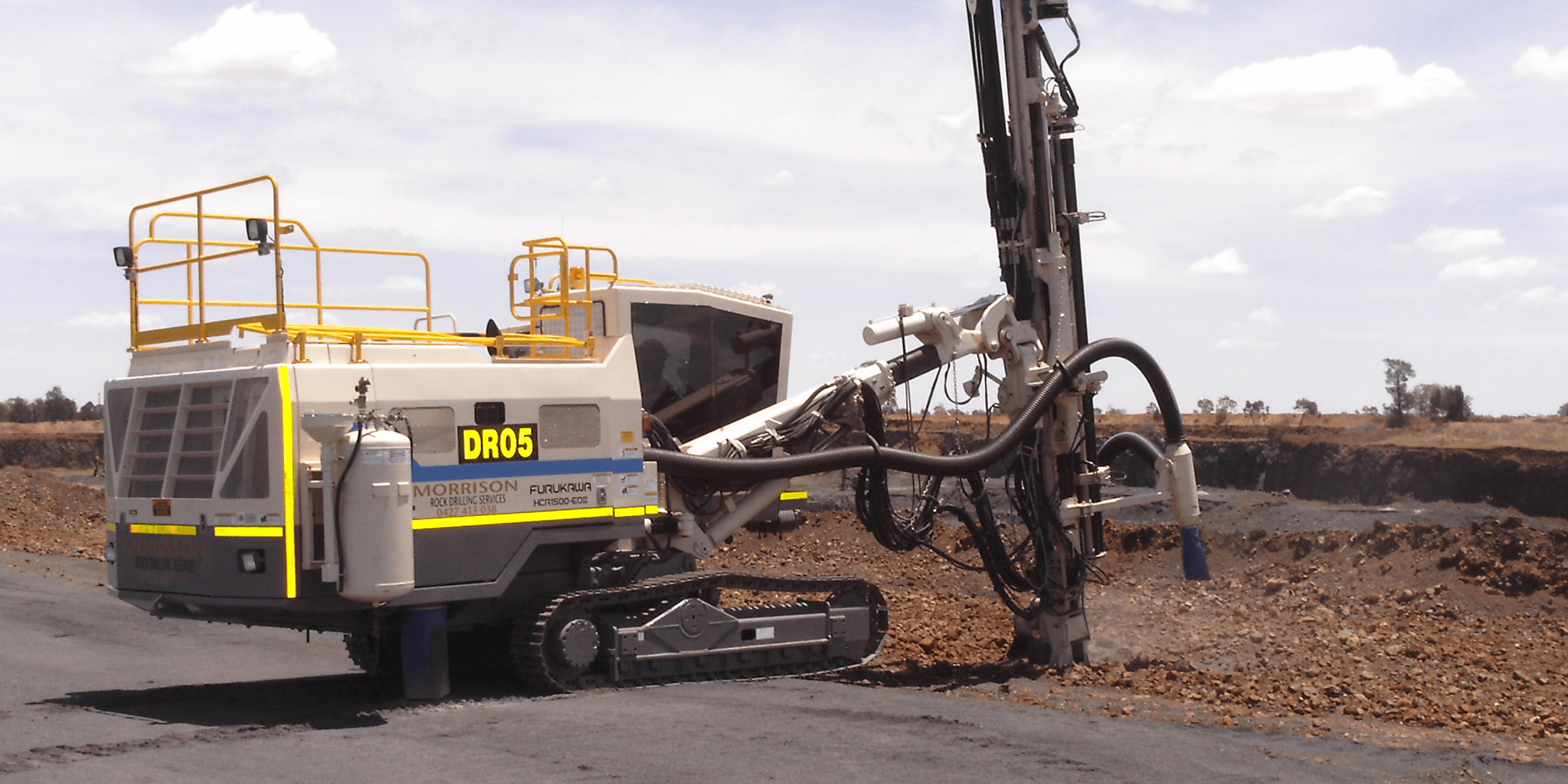

If you have thought about replacing your excavator tracks, its time that you purchase tracks which are well suited for your excavator. With all the latest innovations in technology, it is no wonder that there is a whole lot of variety when it comes to rubber tracks. You might want to take a look at the different types, sizes and tread patterns which are available. Making sure that you have purchased the right track can help you save up in the long run and can also help avoid damage to the undercarriage of the excavator.

What you should look out for when purchasing an excavator track

The first thing that you should consider when purchasing the track is to look at the rubber which has been used and the steel which will hold it together. The right tracks are designed in a way which makes them extra durable so that it can work over uneven terrain and rough surfaces.

There are certain ways by which you can tell a high quality rubber crack from a low quality one. Not all rubber tracks are the same. In fact, manufacturers have been designing tracks since ages and there is so much variety available that it becomes difficult to purchase one which is just right.

You might want to take a look at three or four manufacturers who offer a competitive price. Each excavator is suited to a specific project, so it is essential that you why attract which is in keeping with the purpose for which the excavator is being used.

Choose a track with the right kind of rubber density, which means that it shouldn’t be too hard or too soft. When it comes to good quality rubber, it should be your first priority because it would be able to stand all the stress and strain which is put on it. The rubber that you purchase should be resistant to stretching and puncturing. Although these might cost you a lot more than the usual excavator tracks, they will give you a longer shelf life and higher degree of reliability. They will also provide better performance under all circumstances.

Instead of going for recycled rubber which is prone to splitting open when exposed to harsh conditions and uneven roads, 100% virgin rubber tracks are able to stand all kinds of extreme weather conditions. How would you know whether you have bought a recycled rubber track or a new one? You can smell it by the distinct odor which comes from recycled rubber tracks. It is going to smell like a used tire and it is better that you stay away from any such product so as to avoid problems in the long run. You might also want to take a look at the tracks which should be dark in color throughout and there shouldn’t be any gaps in the color, otherwise it is obvious that it has been designed from recycled rubber.

Make sure that you keep the above-mentioned things in mind when exploring the available options when purchasing excavator tracks.